Our vinification process

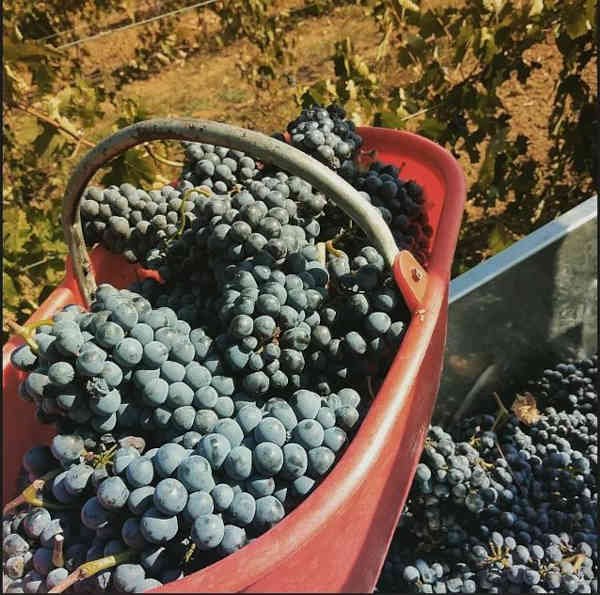

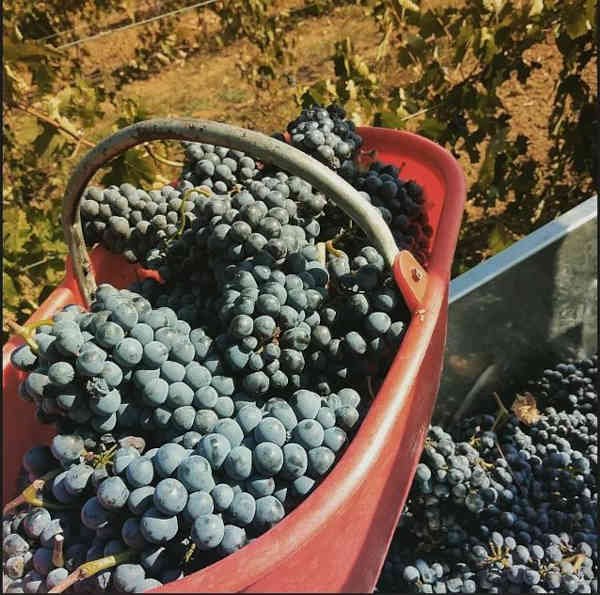

The Harvest

The grape harvest usually takes place in September, when the grapes have reached a stage of ripeness that maximizes the aroma and fragrances of the wine to be produced. In the weeks leading up to the harvest, tests are conducted on the grapes. These tests involve sampling berries from each variety to measure important properties, including sugar levels and acidity.

The ripening of grapes depends on many variables. The most important of which are the ambient temperature, the number of sunny days, and the amount of water during growth.

Red Wine Vinification

The red grapes are harvested into baskets called “cavagne” and then emptied into carts responsible for transporting the grapes from the vineyard to the winery. The first winemaking process, destemming, takes place at the winery, which separates the grapes from the stems. This operation produces a mixture called must, which still contains the grape skins and seeds.

The stems are returned to the vineyards and spread along the rows. It help nourish the soil and enrich it with organic material.

The must, on the other hand, is transported through pipes into a barrel where it begins to ferment. This phase is the most delicate part of winemaking. During fermentation, the sugars in the grapes are converted into alcohol by the yeasts.

The natural yeasts on the grape skins transfer to the must, mainly during the initial destemming and subsequent maceration. In addition to these, we add certified organic yeasts to prevent uncontrolled fermentations. The process during which the must remains in contact with the grape skins is called maceration.

After fermentation, racking takes place, separating the wine from the solid residues (pomace) and transferring it to a storage tank. The pomace is also pressed to obtain additional wine.

Subsequently, the wine begins aging in fiberglass or steel barrels, where it stabilizes. After spending the winter in the barrel, the wine is ready for bottling.

White Wine Vinification

While red wines are obtained through alcoholic fermentation of the must in the presence of the solid parts of the grape, white wines come from the fermentation of only the grape juice. In fact, the destemmed grapes are not immediately sent to the fermentation tanks but first pass through the presses where the separation of the pomace from the liquid part of the must occurs. This process is called “sgrondatura“.

The freshly extracted white grape must is cloudy, containing fragments of skins. After resting at low temperatures for a few hours, the must separates into a clearer liquid and sediments (lees), which settle at the bottom of the barrel. Once filtered, the clear must is fermented at a temperature of 20°C – 22°C to preserve the fresh and fruity aromas.

Sulfite-Free Syrah Vinification

Thanks to the high polyphenol content, we vinify this variety without adding sulfites. In addition to maintaining high standards of cleanliness, as we do for all our wines, we minimize the wine’s contact with air by releasing nitrogen into the tank before filling it with the must. This helps to prevent potential oxidation and the growth of harmful bacteria, which are usually controlled through the use of sulfur dioxide.

Furthermore, the aging of Syrah follows a unique process. After tartaric stabilization in the barrel, the wine is transferred into about 20 glass demijohns, each holding 54 liters, where it remains until bottling.

Sparkling Wine vinification

In 2022, we produced our first white sparkling wine from a vineyard in its first year of production, making 400 bottles using a modified version of the “Ancestrale” method, which avoids residues in the bottles. Since then, we have continued to produce it annually.

The grapes are harvested, destemmed, and pressed within two hours. The juice is fermented at 22°C. When the sugar levels reach 35 g/l, the fermentation is stopped by cooling the must to 0°C, and bottling takes place. Unlike the Classic method, no sugar is added for secondary fermentation.

The bottles are stored horizontally for six months to complete fermentation. Subsequently, they are manually shaken and positioned upside down to allow sedimentation and aging, adding complexity to the wine. This period lasts about six months, with regular rotation of the bottles (“remuage“) to collect the sediments in the neck.

The sparkling wine is then ready for disgorgement (“Dégorgement à la volée“) to remove the natural sediments before being sealed with the classic mushroom cork. Some residues may remain due to the manual disgorgement process.

Monferrato chiaretto vinification

Rosé wine is produced using a combination of both red and white winemaking techniques. We use white winemaking with maceration to create richer and more structured rosé wines.

Our Monferrato Chiaretto D.O.C., made from Freisa grapes, is initially produced following the red winemaking process: after destemming, the juice ferments at 26-27°C with a short maceration to extract color and tannins. Depending on the vintage, maceration lasts from 20 to 36 hours. Once the desired color is achieved, the juice is separated from the skins and completes fermentation at 20-22°C. The Chiaretto is then aged in steel tanks and bottled.